Welding Productivity Calculator

Calculate your welding productivity metrics to optimize your operations

Productivity Results

Formulas used:

Deposition Rate = Filler Used / Welding Time

Welding Speed = Weld Length / Welding Time

Arc Time Efficiency = (Actual Arc Time / Total Time) × 100

Filler Utilization = (Actual Filler Used / Theoretical Filler Required) × 100

Explore More:

- Productivity Calculator

- Productivity Percentage Calculator

- Healthcare Productivity Calculator

- Rehab Productivity Calculator

- Productivity Index Calculator

- Labor Productivity Calculator

Boost Your Welding Efficiency and Cut Costs

Unlock the full potential of your welding operations with our Welding Productivity Calculator. This tool helps you evaluate and improve your welding performance using essential metrics such as weld length, arc-on time, deposition rate, and material usage.

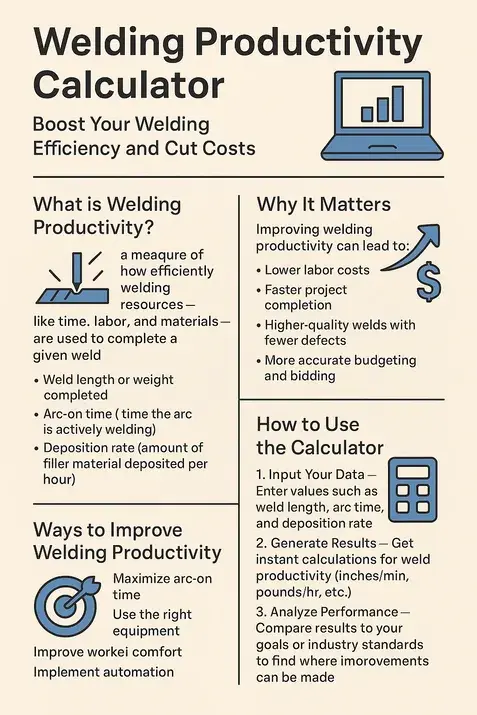

What is Welding Productivity?

Welding productivity is a measure of how efficiently welding resources—like time, labor, and materials are used to complete a given weld. It typically considers:

- Weld length or weight completed

- Arc-on time (time the arc is actively welding)

- Deposition rate (amount of filler material deposited per hour)

By calculating your productivity, you can gain accurate insight into how much work is being completed over a specific time period and identify areas for optimization.

Why It Matter

Improving welding productivity can lead to:

- Lower labor costs

- Faster project completion

- Higher-quality welds with fewer defects

- More accurate budgeting and bidding

Whether you're working with structural steel, pipelines, or custom fabrication, knowing your real-time efficiency can help boost profitability and minimize downtime.

How to Calculate Welding Productivity

To calculate welding productivity, you need to determine how much weld is being deposited over a specific time period. This involves measuring key variables such as arc-on time (the actual time spent welding), the length or weight of the completed weld, and the deposition rate (amount of filler material added per hour). By tracking these values, you can calculate how efficiently your welding process is converting input resources into finished welds. This helps identify delays, optimize labor, and improve overall project efficiency.

Welding Productivity Formula

The basic formula for welding productivity is:

Welding Productivity = (Weld Length or Weight) ÷ (Arc-On Time)

Depending on the unit of measurement, the formula can be expressed as:

- Inches per Minute (IPM) for linear welds

- Pounds per Hour (lb/hr) or Kilograms per Hour (kg/hr) for material deposition

You can also incorporate factors like downtime, rework, or filler metal usage to create a more detailed efficiency model.

How to Use the Calculator

Our calculator is simple to use. Just follow these steps:

- Input Your Data – Enter values such as weld length, arc time, and deposition rate.

- Generate Results – Get instant calculations for weld productivity (inches/min, pounds/hr, etc.).

- Analyze Performance – Compare results to your goals or industry standards to find where improvements can be made.

Real-World Applications

- Project Planning: Estimate the time and cost required for upcoming welding tasks.

- Shift Benchmarking: Compare productivity across different shifts or workers.

- Continuous Improvement: Track productivity over time to see how process changes or equipment upgrades impact performance.

- Maintenance Scheduling: Identify equipment bottlenecks or operator slowdowns by monitoring performance trends.

Ways to Improve Welding Productivity

- Maximize Arc-On Time: Reduce non-welding activities through better prep, setup, and material handling.

- Use the Right Equipment: Choose welding machines and consumables that support your project’s speed and quality needs.

- Improve Worker Comfort: Providing proper PPE and ventilation systems can reduce fatigue and extend arc-on duration.

- Implement Automation: Automated or semi-automated welding systems can drastically reduce cycle times and increase consistency.

- Train & Upskill Welders: Skilled welders with proper technique can significantly increase deposition efficiency and reduce rework.

Unique Features of Our Calculator

- Flexible Unit Options: Choose from linear inches, feet, kilograms, or pounds—whatever matches your workflow.

- Cost Per Weld Insights: Combine labor, filler, and energy costs to calculate your actual cost per inch or per weld.

- Performance Tracking: Use results to track welder performance or compare equipment efficiency.

- Job-Based Reporting: Segment calculations by task, project, or material to support better decision-making.

Put your data to work and drive measurable results. Use our Welding Productivity Calculator to cut waste, improve timelines, and deliver higher-quality welds every time.